POWERTIG 325EXT (~1 PHASE 240V) GTAW-P/ SMAW

POWERTIG 325EXT (~1 PHASE 240V) GTAW-P/ SMAW

Couldn't load pickup availability

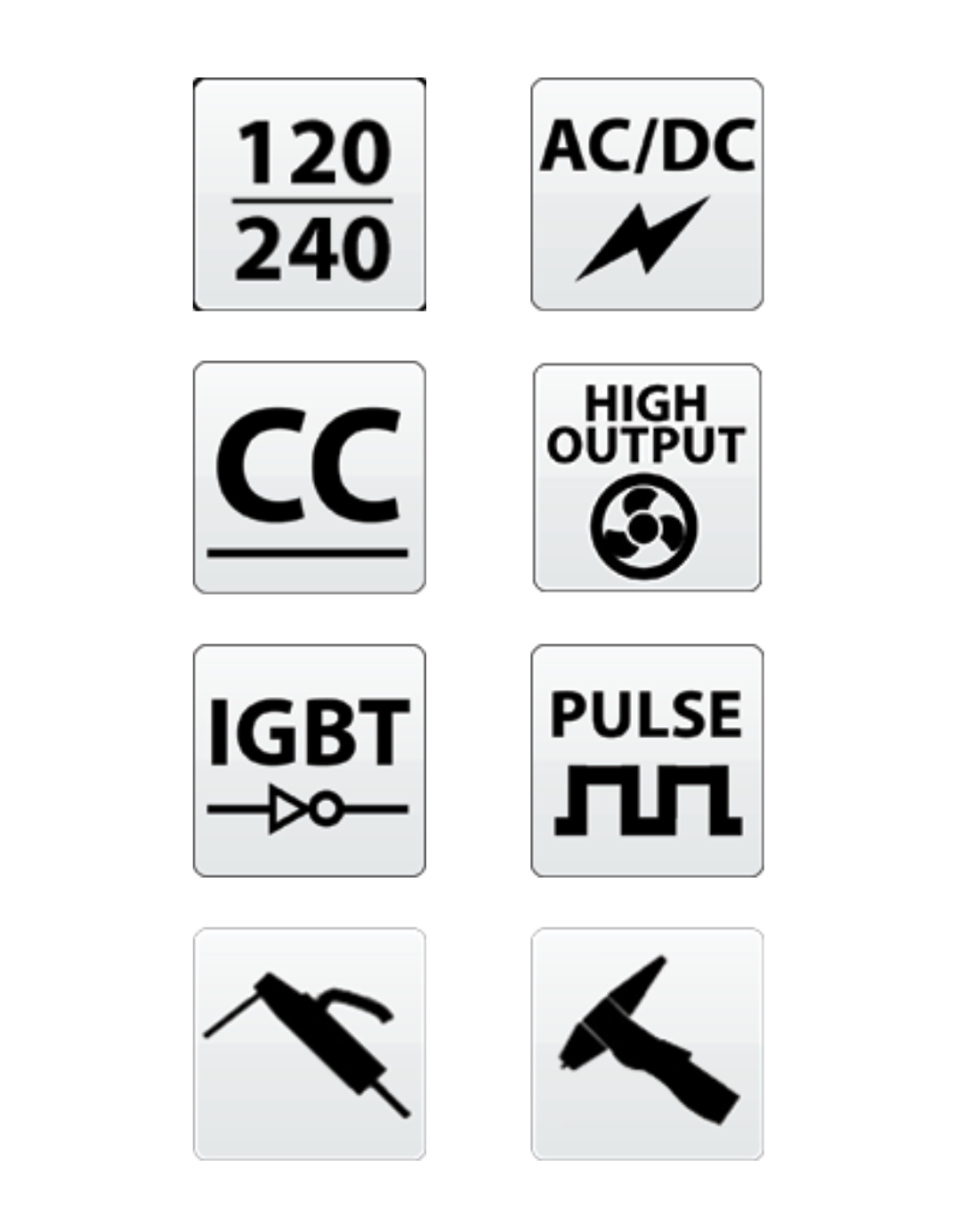

The PowerTIG 325EXT is built for superior industrial performance. With Digital microprocessor control over the IGBT inverter, and up to 325 amps of TIG welding Power, the PowerTIG 325EXT packs considerable punch. The IGBT module inverter design creates a reliable and serviceable platform designed for years of service. The unit is equipped with many features that improve its value in the shop. One of the features that is highly useful is the Advanced Pulse in AC which can greatly increase penetration while welding aluminum, and make it seem like you are welding with a lot larger machine than you are. Wave form control, AC frequency and AC balance control combine to round out the welder into a very capable Aluminum welder. However, the DC capabilities should not be overlooked either with plenty of features which includes a standard pulse frequency up to 500 Hz, and a wide range of adjustable 2T/4T functions. The standard PowerTIG 325 EXT listed here is 240V 1 or 3 phase operation.

NOTE: This unit is for operation with 220/240V 1 or 3 phase operation. For 480V 3 phase operation, please see this separate model listing: PowerTIG 325EXT (~3 Phase 480V).

- Digital microprocessor control

- IGBT Power Modules increase reliability and performance

- Operation down to 5 Amps DC and 10 amps AC

- 2T/4T/ Pedal operation modes with additional 2T/4T mode for torch amptrol operation.

- Wave form control in AC provides 4 wave forms: Sine, Triangular, Soft Square and Advanced Square Wave

- Heavy-Duty High Frequency design reduces maintenance issues and improves start reliability

- No hidden menus to access or complicated set up routines

- Simplified menu design allows settings to be quickly selected and adjusted

- Easy Start Up feature in AC or DC modes to make setup quick and easy for the beginner, or the advanced user

- Pulse up to 500Hz in DC, 250 Hz AC

- 10Hz Advanced AC Pulse mode improves penetration on thicker metals, and can reduce warping and burn through on thinner metals

- Arc force control, Hot start time, Hot start intensity settings for Stick welding to improve performance

- VRD function to help reduce chance of shock or electrocution in areas where a VRD is required or needed for stick welding

- 240 1 phase

TERMS OF SALE AND STANDARD WARRANTY STATEMENT